European manufacturing 100% of our shoes Forclaz are made in Europe

These trekking boots are made in the European Union, in Romania, in a factory specialized in the production of trekking boots (Grisport)

This factory uses exclusively water-based glues, without chemical solvents.

The majority of materials are of European origin.

Manufacturer: https://grisport.it/com

pany/?lang=en

Tip Copy and paste the links you find on this page into your favorite browser.

Dope Dye on the lining of this model

Dyeing textiles requires a lot of water, chemicals and energy. And yet, we love wearing color. To limit this impact, we use the "Dope Dyed" technique, which consists of integrating color pigments in powder form as soon as the yarn is manufactured (and not by soaking in dye baths, as is usually the case). This limits the consumption and discharge of wastewater linked to the dyeing of our fabrics.

The type of course for this shoe

The program for this trekking shoe, the route generally taking place at a higher or lower altitude and/or on an all-terrain route, may be suitable for certain short passages that are a little more technical: passages over scree, névés, gradients, etc.

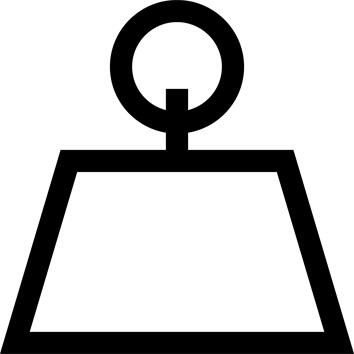

Contact® technology for our insoles

Our soles are Contact® certified

To qualify, the shoe must pass laboratory tests to evaluate its grip coefficient on different surfaces (smooth, rough, dry, wet). To validate these tests, we have the quality of our soles evaluated in the field, in the mountains, by a panel of representative testers over a distance of more than 500 km

Its notching will also provide you with an adapted grip capacity on greasy and wet ground.

Advantages and disadvantages of this leather model

Advantages:

- supple leather.

- resistant and waterproof, leather prevents water from penetrating the shoe by repelling and absorbing it.

- leather is breathable (natural pores in the leather skin), but less so than synthetic shoes in hot weather. To overcome this problem, nubuck leather is more breathable, but also more sensitive to rain.

Disadvantages:

- it needs to be nourished, moisturized and treated to maintain its waterproofing properties.

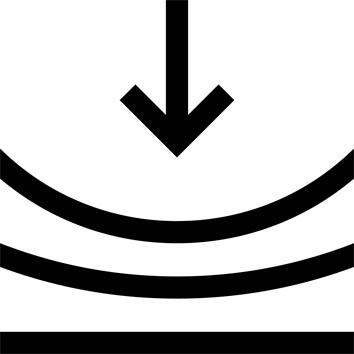

The level of waterproofness of this shoe

This shoe has been waterproofed to 10,000 repeatable flexes, i.e. 15 km of walking in water up to mid-stem. This now guarantees a very good level of waterproofing for our shoes.

--> Our evaluation indicates a level of 3/5, offering waterproofing for 6 hours of hiking in the rain.

Details of the tests carried out to evaluate the waterproofing of our shoes can be found a little further down.

Extend the waterproofing of this shoe. A question of accessories and a little elbow grease!

For leather, we recommend using a waterproof grease to nourish it, prevent it from drying out (cracking), waterproof it and protect it from stains.

1/ Trekking shoe care brush: https://www.decathlon.fr/p/brosse-entretien-chaussures-de-trekking/_/R-p-307665?mc=8551990

2/ Re-waterproofing grease for leather shoes: https://www.decathlon.fr/p/graisse-re-impermeabilisante-pour-chaussures-en-cuir/_/R-p-9513?mc=8229704#zoom=opened

Increase the waterproofness of your footwear with a gaiter

A shoe's waterproofing is often compromised by water intrusion through the top of the shoe.

--> To keep feet dry longer, we recommend the use of a waterproof gaiter or mini-gaiter that will protect the top of the shoe from water intrusion, but also from stones and sand.

Model perfectly suited to this model trekking gaiter MT500 black

https://www.decathlon.fr/p/guetre-de-trekking-trek-500-noir/_/R-p-124466?mc=8347880&c=N

Care for your leather shoes in 6 easy steps

1/ Remove the laces to avoid soiling them with grease.

2/ Dry-brush to remove dust and any particles stuck to the leather. This is essential to prevent the dirt from sticking to the leather with a new layer of grease.

3/ Grease the leather with a brush, so that the grease penetrates deep into all seams and gaps.

4/ Wipe off excess grease with a soft cloth.

5 /Gently rub to shine.

6/ Put the laces back on!

Waterproofing my leather shoes with a water-repellent reactivator

1/ Use a brush and/or sponge to clean the shoe and remove any residues of dirt or mud.

2/ Then leave to dry in the open air, away from a heat source.

3/ Finish by applying a water-repellent spray to keep the upper water-repellent and prolong the life of the shoe.

Link below to the applicator, also available online: https://www.decathlon.fr/p/applicateur-re-activateur-de-deperlance-pour-chaussures/_/R-p-307629?mc=8551

Choosing the right shoe size is a major challenge.

For hiking, don't hesitate to go one size larger than your usual shoe size, to ensure optimum comfort on the way down, and to prevent your toes from banging against the ground. Tip: keep your nails short and check that your lacing prevents your foot from slipping forward.

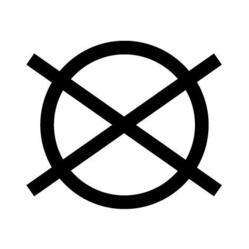

5 levels of waterproofing

In the waterproof test, we test 5 levels of waterproofness:

- 2,000 flexes (approx. 4 km, 30 min walk)

- 10,000 flexes (approx. 10 km, 3 hours walk)

- 30,000 flexes (approx. 15 km, 6 hours walk)

- 50,000 flexes (approx. 20 km, 8 hours walk)

- 100,000 flexes (approx. >20 km, 24 hours walk)

The waterproofing test carried out on this model

Our shoes are tested in the laboratory using 2 consecutive tests.

Test 1: We test the effectiveness of the membrane alone when immersed in water under air pressure. We simply check for the absence of bubbles at the surface, as with a punctured inner tube.

Test 2: Using a mechanical arm to simulate walking, the complete shoes are half immersed in water and flexed thousands of times to check that the inside of the shoe remains dry and therefore waterproof.

Try on your shoes step by step

To choose the right shoe:

1. Try on both shoes, standing, with the socks you use for hiking.

2. Tighten the laces correctly.

3. Check two important comfort points: the heel seat and the forefoot on descents.

4. Stand up to walk with your shoes on.

5. Try on several sizes and models.

6. Use your shoes gradually on the first few hikes to get them to fit your feet.

Main complementary laboratory tests

Laboratory tests are conducted to validate the following elements:

- hook and eyelet pull-out

- sole bonding

- toxicology

- UV resistance

- abrasion of sole and upper components

- accelerated ageing