Back protection

That's the big plus of these freeride overalls. This back protector complies with Personal Protective Equipment standards. It's made of soft PU foam to ensure freedom of movement, and micro-perforated for back ventilation. As it fits inside the overalls, it remains well positioned in all situations. No more back protectors protruding from the pants or out of position!

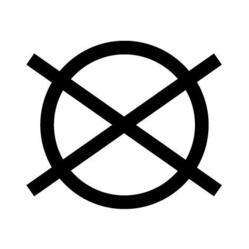

When washing the overalls, simply remove them beforehand.

Water-repellent

The water repellency of a fabric is its ability to let water slide off its surface, without absorbing it. Our freeride pants and overalls are equipped with water-repellent components that prolong their resistance to bad weather. It's an additional technical solution for staying as dry as possible for as long as possible! You need to renew this treatment regularly with products sold in our stores to maintain this performance.

Component impermeability

We measure a fabric's resistance to water pressure expressed in mm water column (test based on ISO 811). The higher the pressure, the more waterproof the fabric. A component with a waterproof rating of 5000 mm will therefore withstand the pressure exerted by 5000 mm of water.

Component breathability

Pour savoir si un tissu est respirant, on mesure sa résistance-évaporative, appelée RET (test normé ISO 11092). C’est la capacité de la veste de ski à laisser échapper vers l’extérieur la vapeur d’eau produite par le corps pendant l’effort afin de rester au sec. Plus la valeur de RET est faible, plus le tissu est respirant.

Par exemple :

RET < 9 = tissu extrêmement respirant

9 < RET < 12 = tissu très respirant

12 < RET < 20 = tissu respirant

RET > 20 = tissu peu ou pas respirant

What's the difference between membrane and coating?

These pants feature a membrane. This is a kind of very thin plastic film (polyurethane) that makes the component waterproof yet breathable. It has the advantage of being more flexible, lighter, more durable and often more breathable than a coating, which is similar to a paint applied to the inside of the fabric, making the component waterproof yet breathable. It is often less expensive than a membrane and requires a lining to protect it.

How do you make a waterproof garment?

A garment's waterproofness is linked to its components, the watertightness of its seams, and the design of its assembly.

The use of waterproof zips or flaps on zips (covering zips with a flap of waterproof fabric).

How do you make a breathable garment?

In addition to the breathability of our fabrics, we use technical solutions (zips, vents, mesh, etc.) to improve the overall ventilation of our jackets and pants designed for freeride skiing. These ventilation systems both regulate the temperature inside the garment and facilitate the evacuation of perspiration generated by the body during exercise.

Your product is repairable

This product is repairable.

During the warranty period, we will repair your product free of charge. Whether it's snags, seams, zips, etc. These solutions will be proposed to you in your usual store.

If, however, we are unable to repair your product (non-repairable production defect), you will be able to exchange it or have it refunded.

What is the Recco® system?

With RECCO® technology, you can be located in the event of an avalanche accident. Equipped with RECCO® reflectors, a buried person can be located quickly and accurately by organized rescue using the RECCO® detector. RECCO reflectors do not replace the use of a avalanche beacon. Complementary in function, RECCO technology increases the chances of being found in time. 100% of our Freeride jackets and pants are equipped with the RECCO system.

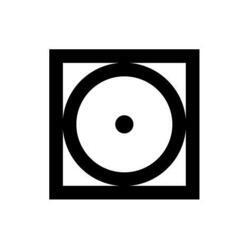

How to wash your waterproof garment

We recommend that you follow this protocol every time you wash your garment, to ensure that it retains all its technical characteristics.

Link: https://youtu.be/rh4GLwALgBM

After three washes, we recommend that you reactivate the water-repellent properties with a spray or impregnation treatment.